Post processing is indispensable for working prototypes or manufactured parts. It provides surface durability and the proper appearance. However, its importance is often ignored. Our major post processing methods include polishing, painting, powder coating, anodizing, and heat treatment.

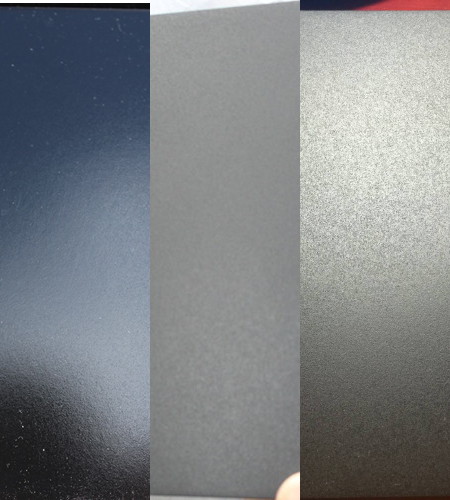

We perform fine adjustments on gloss levels and grain sizes. Painting and powder coating do not only protect, but they also beautify the surfaces. D4E workers can custom paint all kinds of Pantone colors with various finishes. Some finishes resemble the textures from injection molded parts.

Polishing is needed for machined parts, and sometimes for 3D printed parts as well. It is labour intensive, and just like a machinist, a polishing worker also requires years of experience to master the skill. Our workers have decades of experience, to handle this critical step.

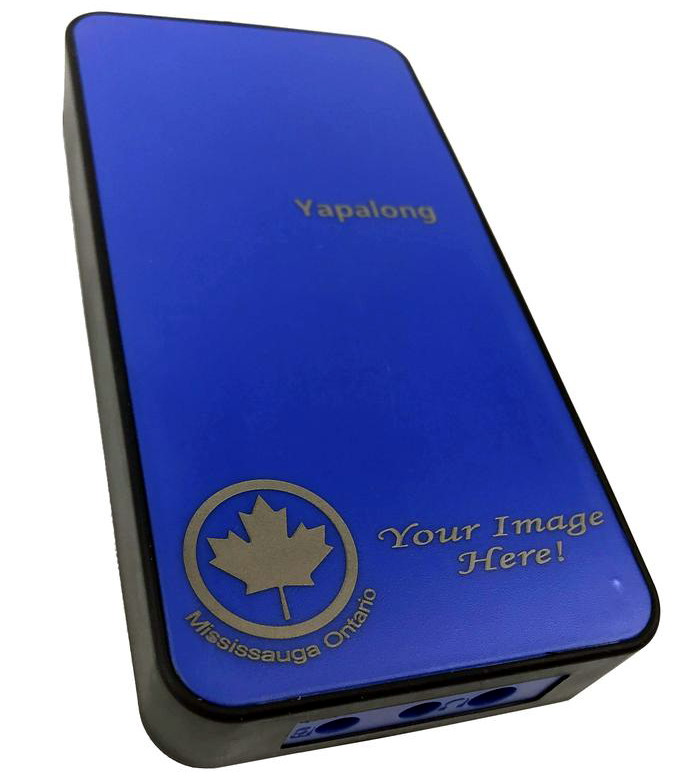

We also provide laser etching and screen printing services.