Sheet Metal

Most of the sheet metal parts we produce are made simply using bending and punching processes. Only a small portion of them require stamping dies, including progressive dies. Stamping sheet metal parts, as opposed to machining, becomes cost-effective at over 150 units, depending on the complexity of the part.

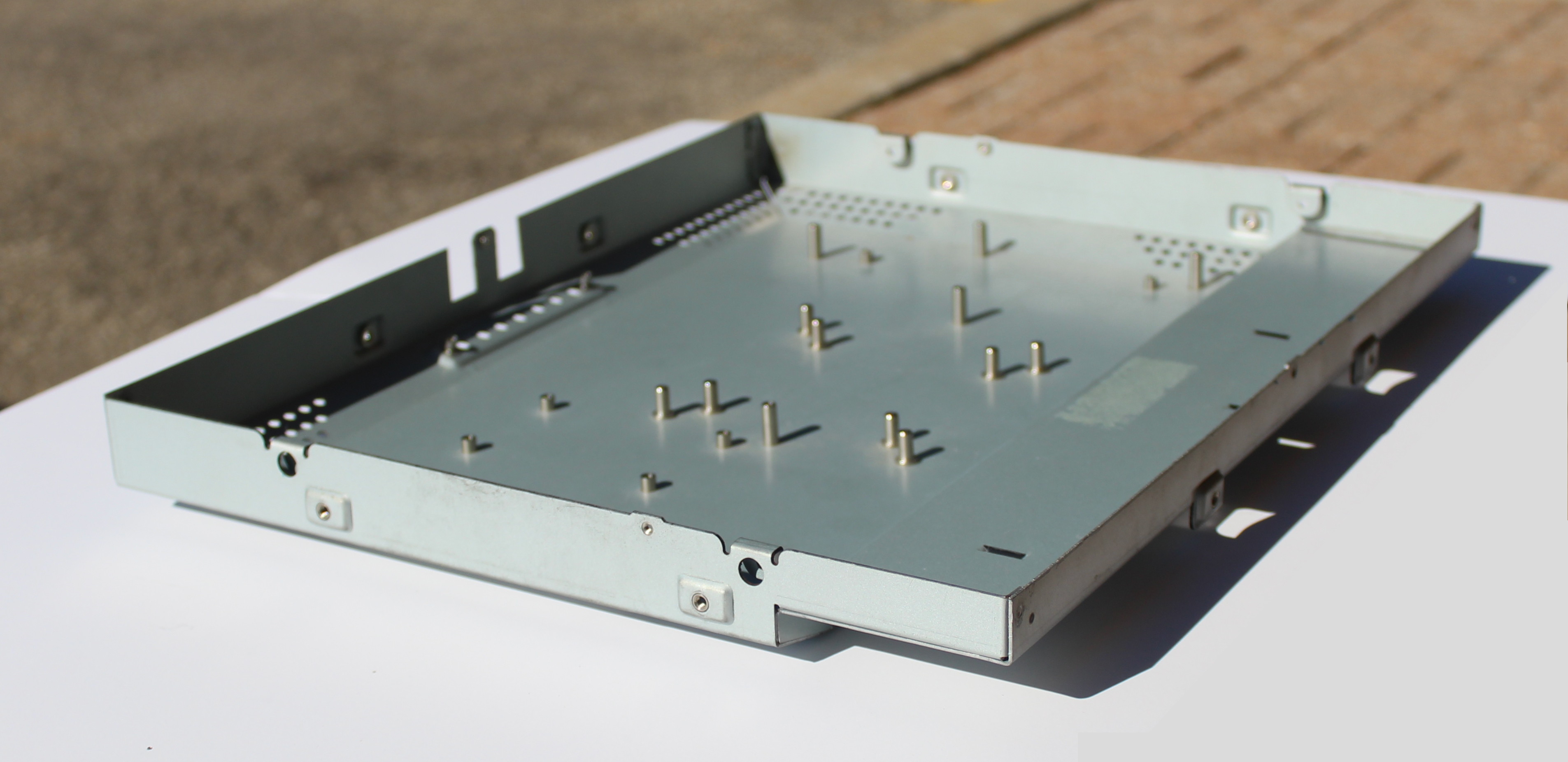

The following chassis part was manufactured using the standard processes of blanking, forming, and bending. It also involved postprocessing procedures of insert-installation and zinc-plating.

Client: Christie Digital

Client: Christie Digital